Projects

Our projects stretches from fundamental research about computational modelling and numerical methods to applied research where we explore new approaches to simulation-based design, control and optimization of heavy equipment, robots and material handling systems.

Over the years we have enjoyed valuable funding from eSSENCE, EU, Mistra, Kempe Foundations, Swedish Energy Agency, Umeå University, Umeå Municipality, VINNOVA and industry partners.

Highlighted projects

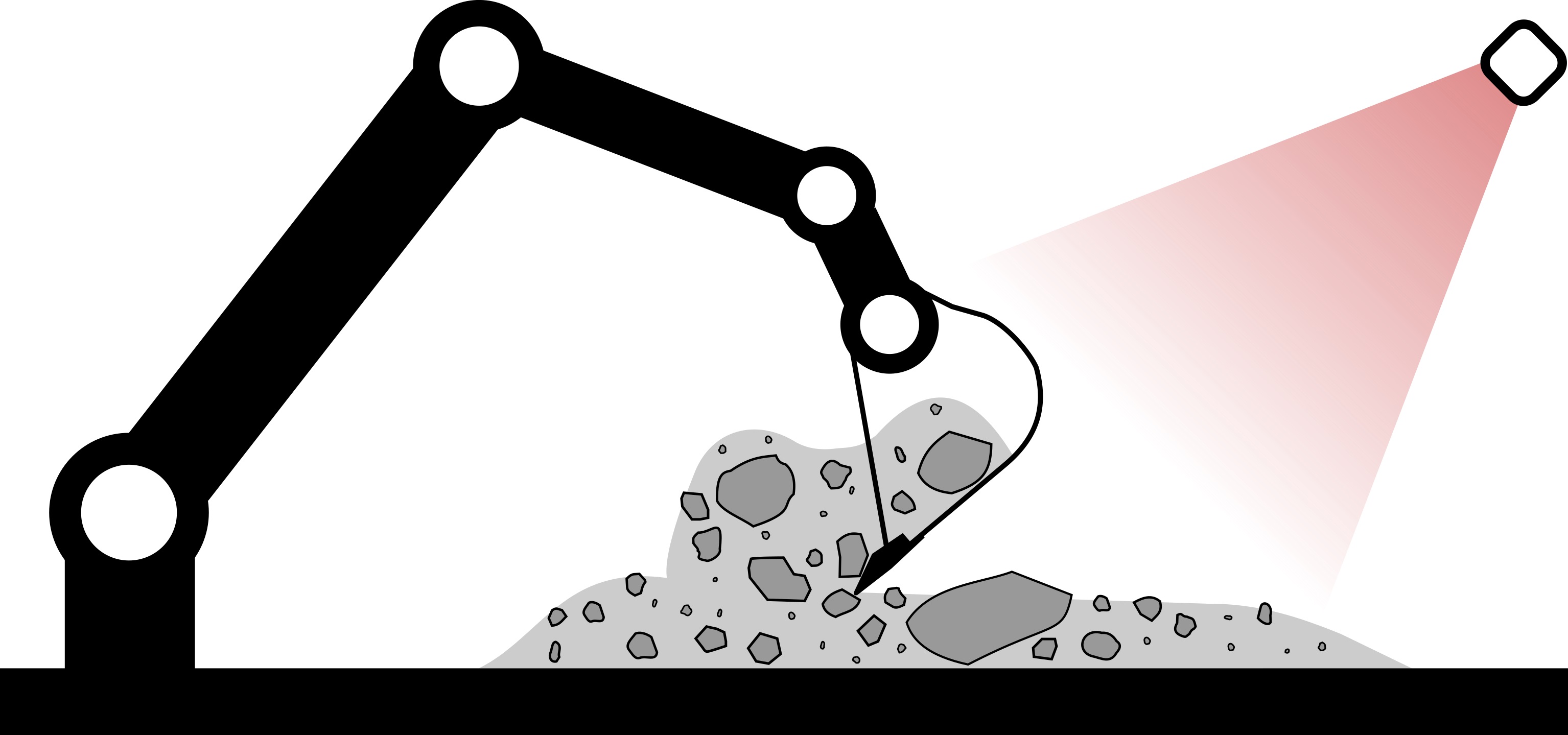

Deep perception in granular materials

The goal is to create physics-informed autonomous manipulation of granular matter. The idea is to learn a dynamics model and the current state of fragmented material in the environment of a mechanical manipulator. The learning takes place in virtual environment where a wide range of different materials and states can be represented, as well as different manipulators and various sensors for creating synthetic training data.

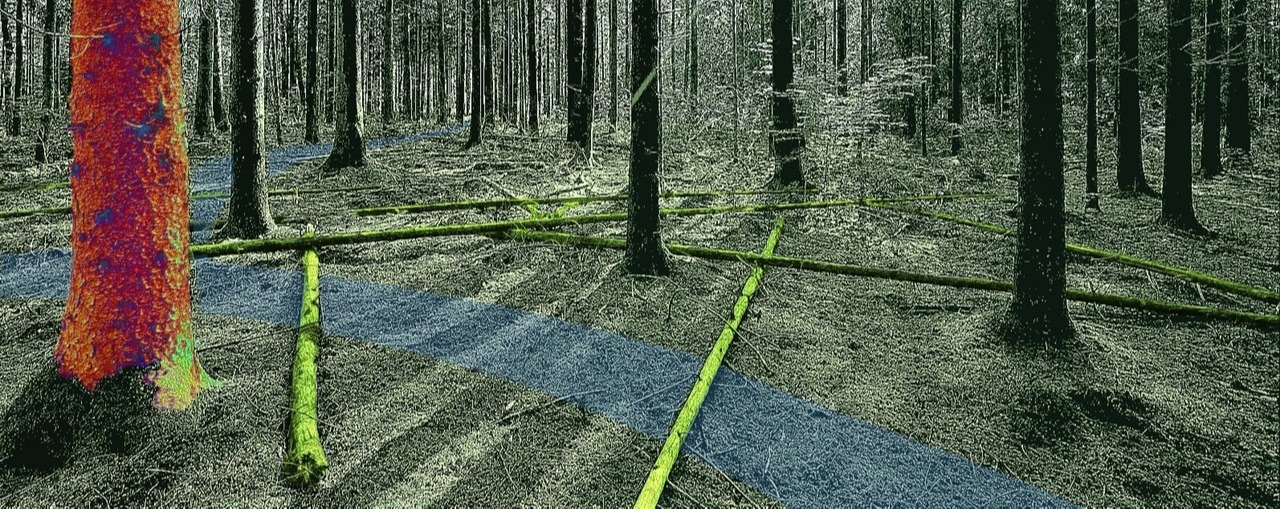

Mistra digital forest

In the national research program Mistra Digital Forest, our goal is to give forest machines capability to perceive their surroundings and predict the outcome of different actions using digital physics and sensor data. Specifically, we focus on driving in rough and weak terrain. Read more on Mistra Digital Forest.

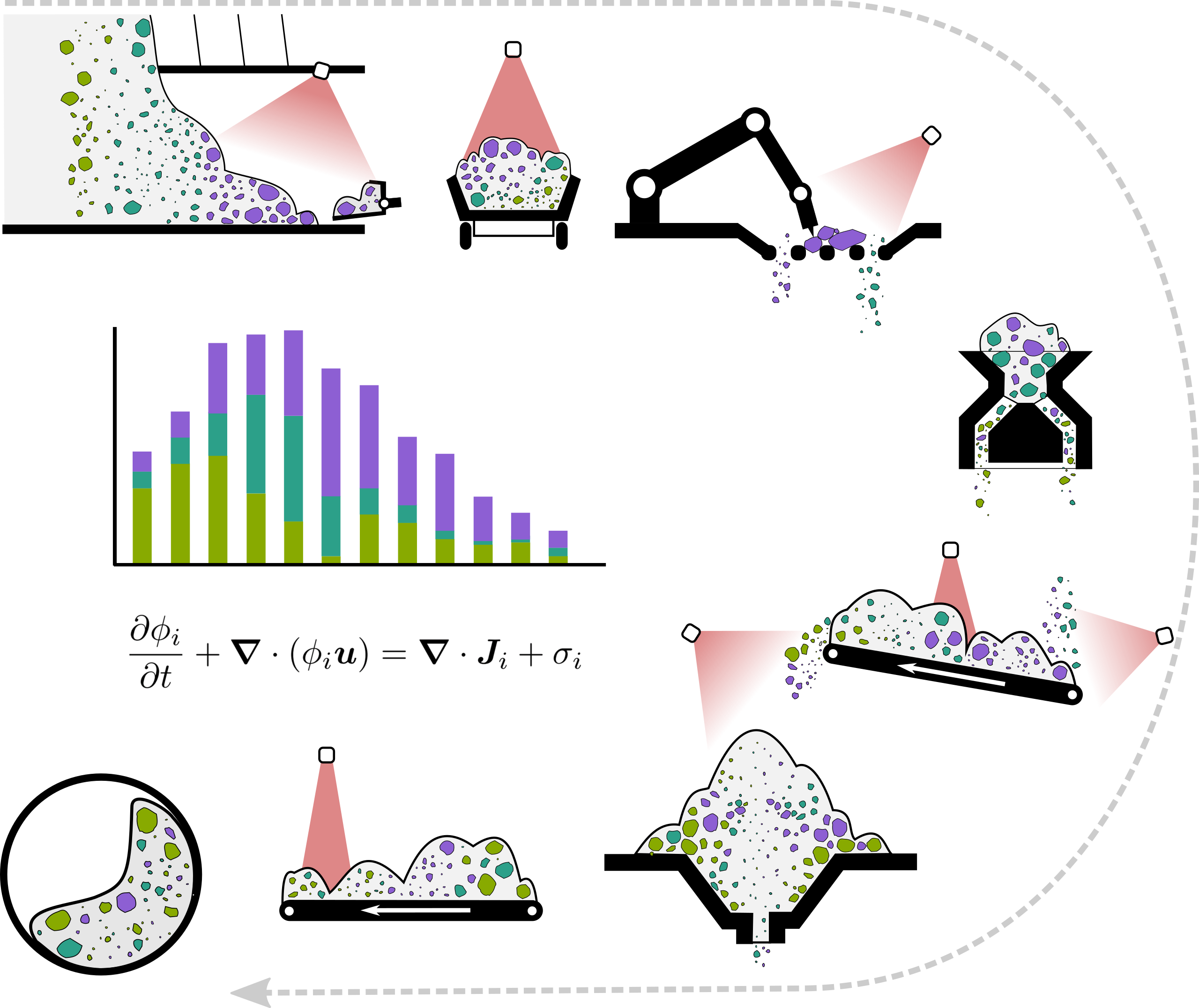

The internet-of-particles

The project research computational methods for handling granular material in digital twins of transportation and processing systems. A particular focus is on enabling development of machine learning models for state determination, tracking and prediction where no real sensors can measure. The results will contribute to a virtual testbed of solutions for fully automated mining operations, to be used both for engineering and academic research.

A digital twin is a virtual replica of a real cyberphysical system, like manufacturing or processing plant, or a vehicle. It is based on a large collection of physics-based and geometric models in conjunction with controllers and sensor data in an IoT infrastructure. The digital twin functions as an interface to the real system, making it more easily accessible for monitoring, analysis, machine learning and, ultimately, creating software applications for smart control, predictive maintenance and early detection of risk for catastrophic failure. The major benefit of digital twins is the possibility of experimentation using full-system simulation to investigate radical changes in control strategies and system design. Physics based simulation enables also determination of the internal state in processes and measurement of quantities that are hidden in the real system for practical or fundamental reasons.

SMIG

In the project we develop and test how high-fidelity granular simulation can be accelerated to real-time performance and applied to on-line tracking of material in mines and processing plants.

SMIG is short for Integrated Smart Test environment for the mining industry. The project partners include ABB, Algoryx Simulation, BnearIT, Boliden Mineral, Epiroc Rock Drills, Ericsson, IBM, Luleå University of Technology, Nordic Rock Tech Centre, Sandvik SRP, Siemens, Svensk kärnbränslehantering, ThingWave, Umeå University, Uppsala University and Volvo Construction Equipment.